Surface and subsea applications include:

- Wellheads

- Valves

- Blow out preventors

- Umbilicals

- Drilling tools

- Subsea Pumps

- Offshore cranes

- Pipeline skids

Oil & Gas

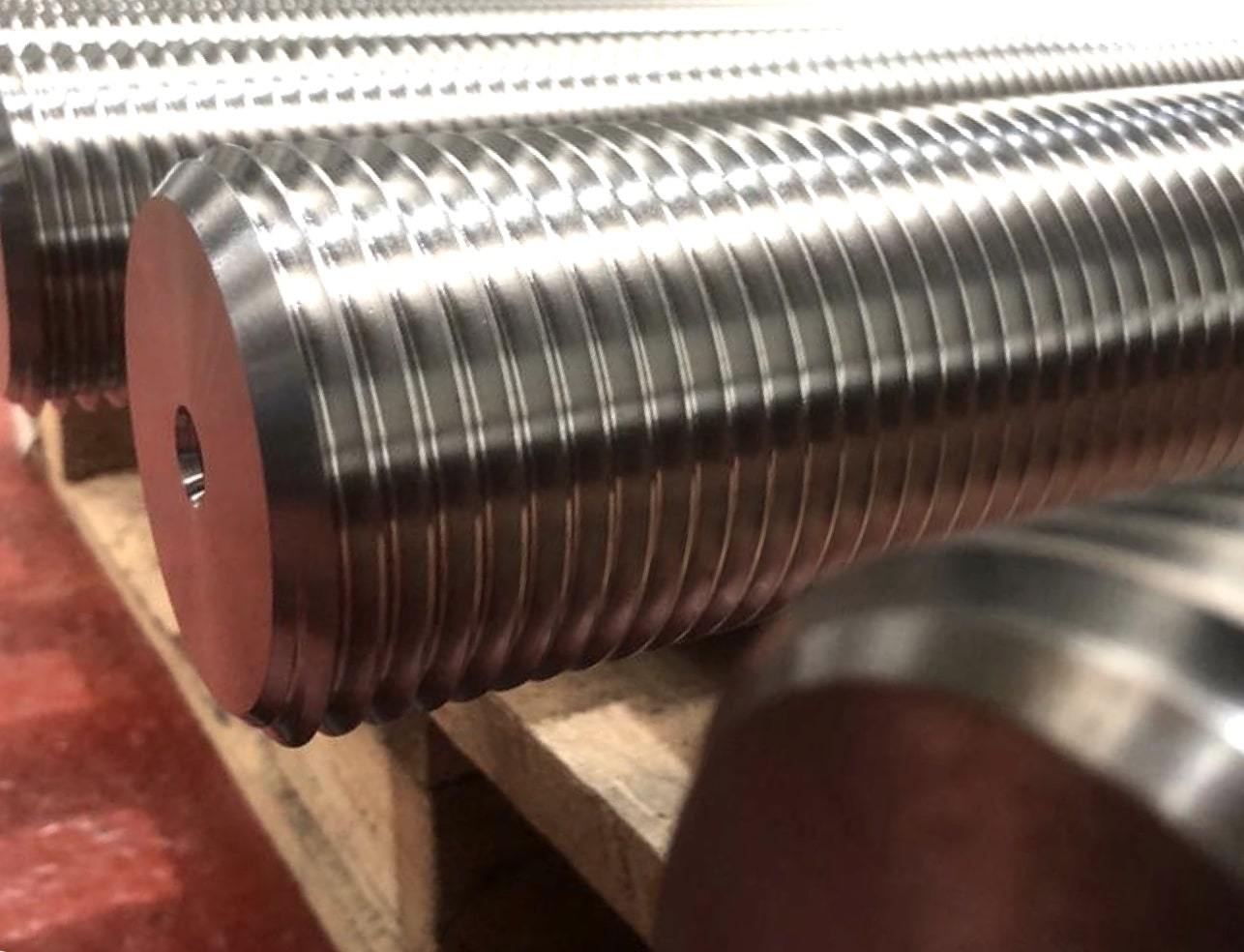

High integrity products supplied in a

sustainable manner

Hydrobolt Group's products are used extensively in both surface and subsea applications where product integrity is paramount in these harsh environments.

Surface and subsea applications include:

Fasteners often have to be certified to API20E/20F or NORSOK M650 D59 or D60, and for sour environments, NACE requirements frequently have to be met.

Companies transporting oil & gas from the upstream locations, working on FPSO projects and LNG plants feature heavily in Hydrobolt Group’s client portfolio.

Third party witnessed 3.2 certified fasteners and low temperature testing are commonplace within this sector.

Oil & gas downstream refineries have many areas on the plant where ASTM A193 B7, B8 & B8M grade studbolt assemblies are used, including:

Equipment and plant on petro-chemical facilities often transports highly corrosive liquids and gases resulting in exotic alloys such as Hastelloy, Titanium & Inconel having to be used.